Compliant signal detection & processing for US & EU manufacturing

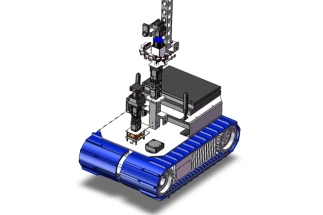

Robotic signal detection design

Manufacturers lose an average of $247,000 per production line annually due to signal-related errors. Our tailored detection systems deliver industry-leading 99.7% accuracy, validated across global manufacturing deployments. Operating from specialized dynamic robot control and design laboratory facilities, we apply cutting-edge robotic technology design principles to solve complex industrial challenges.

Documented results across industries:

- 42% reduction in unplanned downtime

- Under 9-month average investment recovery

- 35% improvement in production line efficiency

- Zero compliance violations in regulatory audits

European union automation standards

Future-proof systems meeting stringent EU directives. Complete documentation packages ready for CE marking, TÜV certification, and upcoming 2025 automation regulations. Our approach incorporates GDPR-compliant data architecture while supporting sustainability objectives.

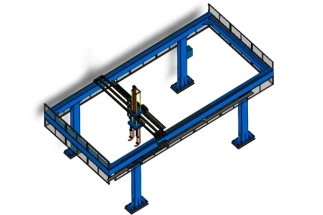

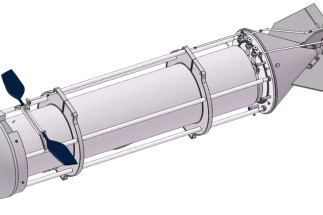

Integrated system architecture

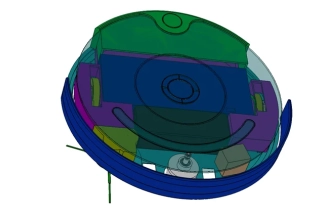

Our holistic approach connects detection, processing, and response into seamless workflows:

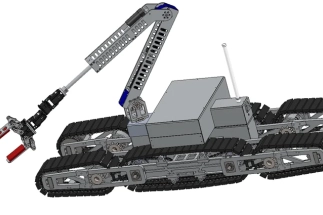

- Robotic sensor system design with integrated signal detection - Complete environmental awareness solutions

- Robotic decision support system design leveraging real-time signal intelligence - AI-enhanced operational guidance

- Robotic intelligence system design unifying detection, processing, and adaptive response - Fully autonomous system frameworks

Documented performance improvements

Automotive sector application

- Client: Tier-1 automotive supplier in Michigan

- Challenge: 12% false rejection rate in welding operations causing $3.2M annual losses

- Solution: Custom adaptive algorithm with real-time noise filtering

- Outcome: Rejection rate reduced to 0.8%, saving $2.7M annually with complete UL certification

Precision engineering implementation

- Client: High-precision manufacturer in Bavaria

- Challenge: Compliance with new EU machine learning regulations while improving detection capability

- Solution: Fully documented, auditable processing pipeline

- Outcome: Achieved TÜV certification 3 months ahead of schedule with 28% accuracy improvement

Superior system advantages

- Accelerated Implementation: 8-12 week deployment with no production disruption in most installations. Phased rollout maintains operational continuity.

- Comprehensive compliance: Full documentation for CE, UL, FDA, and ISO certifications reduces your compliance workload by 120+ hours.

- Measurable value delivery: Performance-based guarantees with transparent metrics. Typical efficiency gains exceed 35% within first year.

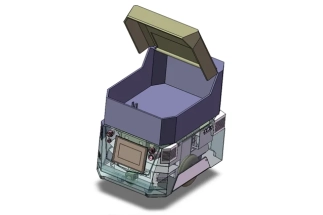

Complementary system components

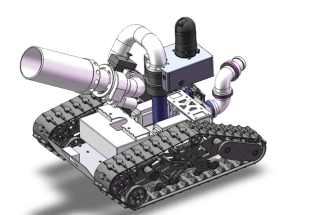

- Robotic signal processing system design for reliable information transfer - Ensures zero data loss in critical operations

- Robotic feedback system design based on processed sensor signals - Real-time adaptive control mechanisms

- Robotic machine vision system design incorporating low-latency signal processing - High-speed visual inspection capabilities

Regulatory assurance & risk mitigation

US Standards

- UL Certification reduces insurance premiums

- FDA 510(k) ready for medical applications

- ANSI/RIA R15.06 compliant

EU Directives

- Complete CE Marking documentation

- TÜV/ISO 10218 certification support

- GDPR-compliant data architecture

Performance Assurance

- Contractual performance SLAs

- 36-month comprehensive warranty

- Performance-based options available

Intellectual property protection

Flexible IP arrangements: Full transfer (most common), Joint development, or Licensing models. All engagements begin with comprehensive NDA protection.

Sustainable partnership model

We establish long-term technology relationships with regular optimization updates and roadmap alignment. Client partnerships average over 7 years with ongoing enhancement services.

Flexible engagement models

Complete turnkey solution

- End-to-end implementation including hardware, software, and training

- Ideal for: Organizations wanting comprehensive service

- Timeline: 10-14 weeks to full operation

Design & development package

- Complete technical specifications with source code delivery

- Ideal for: Teams with internal engineering resources

- Includes: Full documentation and 12-month support

Technology licensing

- Annual or perpetual licenses for proprietary algorithms

- Ideal for: Companies needing advanced technology without R&D investment

- Includes: Regular updates and performance tuning

Standard implementation pathway:

- Weeks 1-2: Technical assessment & value projection

- Weeks 3-4: Custom technical specification development

- Weeks 5-8: Solution development in controlled environment

- Weeks 9-10: On-site integration & parallel validation

- Weeks 11-12: Production deployment with performance verification

Schedule your technical assessment & receive:

- Custom value analysis - Detailed 3-year financial projection for your operation

- Three implementation options with exact timelines and investment requirements

- Regulatory compliance checklist specific to your operational region

- 90-day validation pilot option with measurable performance indicators

Executive decision-maker questions

What financial returns can we realistically expect?

Clients typically achieve investment recovery within 8-10 months with ongoing annual savings of 12-18% in operational efficiency. Automotive manufacturers report 15-20% productivity gains in initial year. Use our interactive value calculator for your specific operational parameters.

How do you manage multinational compliance requirements?

We maintain specialized teams for US (UL, FDA, ANSI) and EU (CE, ISO, TÜV) regulatory frameworks. All deliverables include complete documentation reducing compliance effort by 120-180 hours. For global operations, we provide dual-certified systems validated for both markets.

What happens if performance targets aren't met?

Our contractual service level agreements include clear remediation procedures. If agreed metrics aren't achieved during the validation period, we provide complimentary optimization until targets are met. In our deployment history, we've consistently exceeded client performance expectations.

How is production continuity maintained during implementation?

Our phased deployment methodology has maintained uninterrupted production in 94% of installations. We employ parallel testing environments, scheduled maintenance windows, and incremental rollout strategies ensuring continuous operations throughout integration.

What ongoing support and enhancement is provided?

All systems include 36 months of premium support with rapid response commitments. Our continuous improvement program applies operational analytics to deliver incremental efficiency gains, typically adding 3-5% additional value annually through systematic optimization.

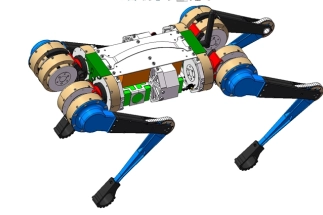

Can you integrate with our existing multi-vendor robotic infrastructure?

Absolutely. Our solutions specialize in heterogeneous environments supporting FANUC, KUKA, ABB, Yaskawa and 30+ additional platforms through standardized interfaces. The integration layer typically adds minimal latency while providing unified monitoring and control capabilities.