CNC Machine Tool Design Services

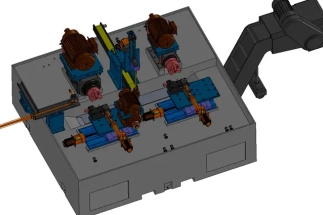

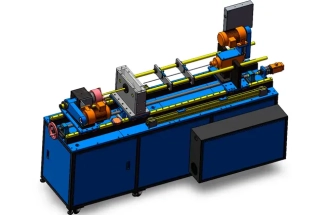

CNC machine tool design

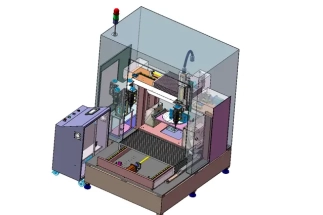

A trusted machine tool design company providing complete CNC machine tool design solutions. We handle every stage of development, from concept sketches to 2D drawings, 3D drawings, and full technical documentation. If you wish to buy or order a design, we offer transparent design cost estimates and expert consultation.

Why choose our CNC machine tool design company

- Specialized in custom machine tool design and engineering design consulting

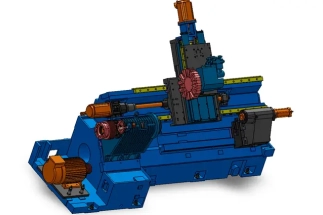

- Comprehensive expertise in spindle, gearbox, and fixture design

- Deliverables include verified 3D and 2D drawings with detailed technical documentation

- Clear communication and step-by-step approval process

- Competitive design cost with full IP ownership upon completion

Our machine tool design services

- Frame, bed and Structural design: We develop machine tool frame designs and machine tool bed designs that minimize vibration and thermal drift. Using finite element analysis (FEA), we guarantee strength and precision alignment under load.

- Fixture and tooling design: Our fixture design for CNC machine tools ensures optimal rigidity, repeatability, and ease of operation. Combined with tool design and machining knowledge, we create ergonomic and safe solutions.

Learn more about our fixture design process or spindle optimization methods.

Technical documentation and drawings

We deliver precise 2D drawings (DWG, PDF) and 3D drawings (STEP, IGES) containing all dimensions, tolerances, and material specifications. Each project is supplied with manufacturing-ready technical documentation.

Key factors in CNC machine tool design

- Dynamics and Kinematics: We address all design considerations of CNC machine tools, including motion control, acceleration, and damping. Kinematics in machine tool design is simulated to ensure smooth movement and positioning accuracy.

- Ergonomics and Usability: Ergonomics in machine tool design ensures operator comfort, safety, and efficiency. Controls and access panels are positioned to reduce fatigue and enhance productivity.

- Tribology and Durability: We apply tribology considerations in machine tool design to reduce wear and extend tool life. Precision lubrication systems and surface treatments are selected for optimal performance.

- Design requirements and Calculations: Our engineers follow the general requirements of machine tool design and perform accurate machine tool design calculations. We use the preferred number in machine tool design method to achieve balanced component dimensions and performance. All projects comply with national machine tool design standards and ISO regulations.

- Recommendations and Modularity: By applying machine tool design recommendations from academic and industry sources, we develop a modular design for machine tools that simplifies maintenance and upgrades.

Design cost, Ordering and process

The design cost depends on complexity, deliverables, and revision stages. To order a design, follow these simple steps:

- Consultation and requirement analysis

- Preliminary concept and quotation

- Contract and payment deposit

- Detailed machine tool design process and modeling

- Client review and design optimization

- Final delivery of documentation and CAD files

For more details, order a design or request a free quote today.

About our engineering expertise

We are one of the most experienced engineering design companies in the field of precision manufacturing. Our certified machine tool designers and mechanical engineers hold advanced degrees and over 15 years of industry experience.

Our projects include custom machine tool fixture designs, automation tooling, and spindle systems for aerospace, medical, and industrial automation clients.

All services are backed by strong quality assurance and adherence to international machine tool design requirements.

Frequently Asked Questions

- What determines the design cost?

- The total design cost depends on the number of assemblies, complexity, and requested accuracy level. Smaller projects start at lower rates, while multi-axis systems require more hours of engineering time.

- What is included in the final documentation?

- The final delivery includes full technical documentation, 2D drawings, 3D models, assembly instructions, and material specifications.

- Can I buy or order only one component?

- Yes, you can buy or order individual modules, such as fixture design, spindle design, or frame layout.

- How long does the design process take?

- Most projects take 3–8 weeks depending on complexity, analysis, and review cycles.

Get started

Ready to buy or order your next CNC machine tool design? Contact us today to receive a personalized quote and discuss your project specifications with our design consultants.