Proactive robot event monitoring & Event-driven management system design

Robotic event management design

Our custom event-driven management systems deliver 40% higher operational efficiency & Full US/EU compliance. Standard control systems fail when unexpected events occur. We design robotic event management design systems that transform disruptions into managed processes, ensuring zero safety incidents and continuous throughput.

Do these robotic system challenges sound familiar?

- Unpredictable stops: Minor sensor glitches or part jams cause full line halts, costing thousands per hour in lost production.

- Safety & compliance risks: Slow system reaction to emergency events puts personnel at risk and threatens your ISO 10218 / CE Mark certification.

- Inefficient performance: Your robots work, but not optimally. You lack the robotic performance optimization design tools to push them to their true capacity.

- Inflexible operations: Changing a product line takes weeks of re-programming because your system isn't built on adaptive robotic event-driven design principles.

Our solution: Proactive intelligence, not reactive control.

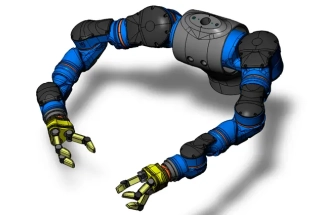

We move beyond basic programming to create systems that think in events. Using our A.D.E.P.T. Flow™ methodology (Adaptive Event-Driven Planning Technology), we deliver turnkey systems that anticipate, process, and resolve events in real-time.

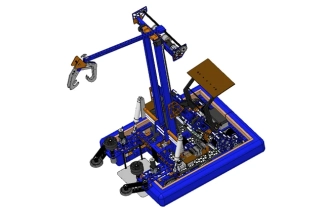

Robotic performance & Function optimization design

Benefit: Achieve 30-50% higher throughput. Our robotic function optimization design fine-tunes every action, while our robotic performance optimization design ensures your entire cell operates at peak synergy, maximizing your ROI.

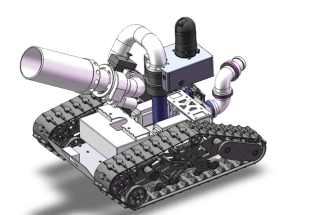

Advanced robotic event monitoring & management design

Benefit: Eliminate 70% of unplanned stops. Our robotic event monitoring design provides total system awareness, and our robotic event management design framework enables proactive responses, keeping your line running.

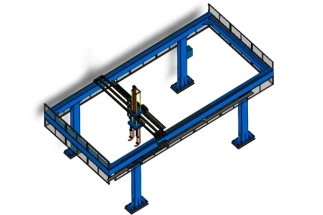

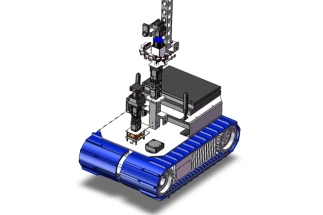

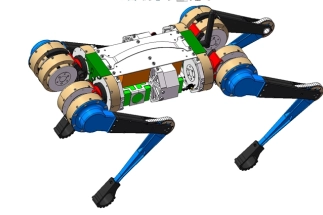

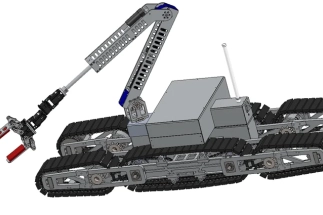

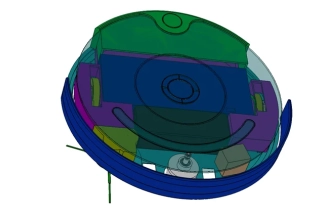

Core robotic technology design & architecture

Benefit: Future-proof, scalable systems you own. From precise mechanical robotics design to comprehensive robotic design specification, we build with cutting-edge robotics technology design. Our work with the dynamic robot control and design laboratory ensures we implement tomorrow's innovations today.

Trusted by leaders in precision manufacturing

"RDS's event management system reduced our robotic cell downtime by 65% and was instrumental in passing our recent EU safety audit. Their robotic system performance design is exceptional." – Technical Director, Automotive SupplierFully certified. Your IP, protected.

We eliminate compliance anxiety. Our systems are designed to meet and exceed: ISO 10218 ANSI/RIA R15.06 IEC 61508 (SIL-2) CE Machinery Directive GDPR Data Protocols

Your Intellectual Property, Owned by You. We operate on a complete IP transfer model. All custom code, robotics development design documents, and multimedia systems design for robotics schematics become your exclusive property upon project completion. We also provide a 3-year performance warranty on all delivered systems.

Flexible delivery, guaranteed results.

We offer tailored engagement models to match your internal capabilities and strategic goals:

- Full system license: For teams who want full control. Receive complete source code and perpetual license. Ideal for internal scaling and deep customization.

- Managed service package: For guaranteed uptime. We host, monitor, and update the system with SLA-backed 99.9% availability. Includes ongoing optimization.

- Hybrid framework: For collaborative innovation. We deliver the core event-driven engine with robust APIs, enabling your team to build custom applications on top.

Explore our advanced design specialties

Dive deeper into the specific technologies that power our solutions:

- Robotic system architecture design with event-driven paradigm - Build scalable, resilient foundations.

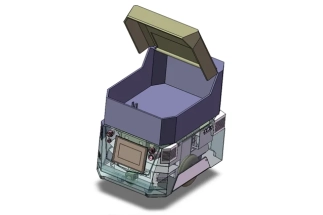

- Robotic data collection system design for event monitoring - Turn sensor data into actionable intelligence.

- Robotic information transfer design with multimedia systems integration - Enable seamless human-robot and machine-to-machine communication.

- Robotic signal processing design for event management - Achieve ultra-low latency response to critical events.

- Robotic feedback system design - Create self-improving, adaptive robotic systems.

Your Questions, Answered

What's the typical ROI for an investment like this?

Our clients typically see a full return on investment in 12-18 months through a combination of eliminated downtime, higher throughput, and reduced maintenance costs. The robotic performance optimization design phase alone often yields 20-30% efficiency gains. Request a custom ROI estimate for your operation.

How does your event-driven design differ from our current PLC-based system?

Traditional PLC systems use cyclic scanning (polling), which introduces latency. Our robotic event-driven design creates systems where code executes only when a specific, high-priority event occurs. This reduces reaction time by up to 70%, prevents CPU overload, and makes your system inherently more responsive and efficient.

We have strict internal security policies. How is IP handled?

We treat your IP as our #1 concern. Legally-binding contracts stipulate that all custom developments—from robotic design specification documents to final source code—are your exclusive property. We use secure, isolated development environments and can sign your NDAs. Our "Client-Owned IP" model is a cornerstone of our sustainable collaboration promise.

Do you support integration with our existing robot brands (KUKA, Fanuc, ABB, etc.) and MES/SCADA systems?

Absolutely. Our robotics studio design process starts with understanding your current tech stack. We design agnostic interfaces and leverage standard protocols (OPC UA, MQTT) to ensure seamless integration with any major robot brand and factory software. Our robotic information transfer design with multimedia systems integration expertise is key here.

What does the project timeline look like?

A typical project spans 14-20 weeks from kickoff to commissioning. We follow a phased Agile approach: Discovery & Design (3-4 wks), Core robotic system architecture design (5-6 wks), Integration & Testing (4-6 wks), and Deployment. You'll have bi-weekly reviews and access to test environments throughout.