Custom robotic decision-making system design: Achieve 40% cost reduction with intelligent decision support

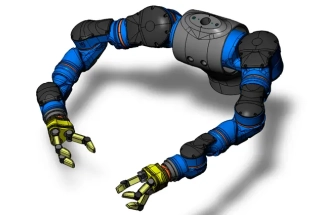

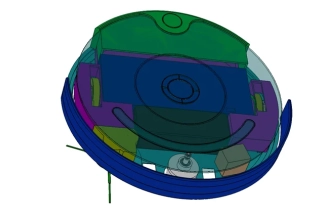

Robotic decision-making system design

Start investing in robotic systems that think, adapt, and optimize - delivering measurable ROI in 12-18 months.

- Sky-High labor variance: Your fixed robots can't handle product variation, forcing expensive human intervention and causing 15-30% labor cost overruns.

- Inability to scale profitably: Adding capacity means buying entire new cells with linear cost increases, not smart software upgrades.

- Compliance & Safety risks: EU's Machinery Directive and US OSHA evolving standards make off-the-shelf solutions a liability minefield.

- Vendor lock-In: You own the hardware but rent the "brain" through expensive annual licenses, with no access to core algorithms.

Our design philosophy: Intelligence as a capital asset

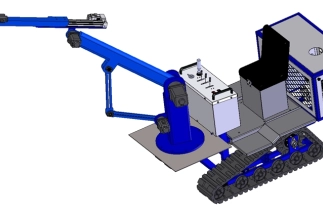

Unlike typical robotics technology design shops, we don't just build what you ask for. We engineer appreciating assets-systems that learn and improve, owned entirely by you.

Why leading US manufacturers & EU Precision engineers choose us

- Guarded IP & No lock-in: You own 100% of the custom robotic decision-making system design and algorithms.

- Dual-Regulation compliance built-In: Systems pre-validated for both ANSI/RIA (US) and CE/Machinery Directive (EU) requirements.

- Measurable ROI guarantee: We contractually commit to achieving the KPIs defined in our joint financial model.

- Legacy Integration expertise: We connect new intelligence to your existing Siemens, Rockwell, or SAP infrastructure.

Your roadmap to measurable ROI: A proven 4-Phase partnership

- Phase: Outcome alignment & financial modeling (Weeks 1-2): We don't start with technical specs. We start with your CFO's goals. We conduct a deep-dive analysis to build a robotic system performance design model tied to specific financial outcomes: cost-per-unit reduction, throughput increase, or quality cost avoidance. You receive a detailed ROI projection before any design begins.

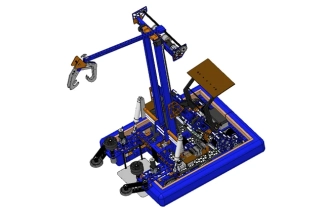

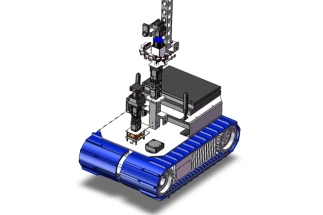

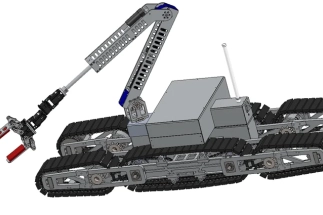

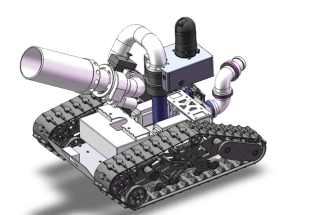

- Phase: Risk-Free prototyping in our digital twin lab (Weeks 3-10): Before touching your production line, we develop and test the core robotic decision support system design logic in our dynamic robot control and design laboratory using digital twins of your environment. This phase de-risks the project by validating key algorithms for robotic function optimization design.

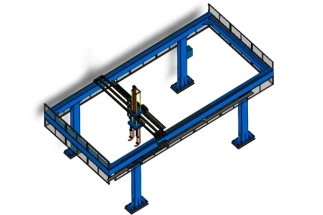

- Phase: Full deployment & Your team empowerment (Weeks 11-20): We deploy the complete system with seamless integration to your existing PLCs and ERP. Crucially, we train your engineers on system maintenance, optimization, and modification-ensuring true ownership. This includes deep knowledge transfer on the robotic system architecture design and robotic machine vision design components.

- Phase: Continuous optimization partnership (Ongoing): We shift to a performance-based retainer, continuously analyzing system data to suggest and implement improvements to the robotic decision-making and task scheduling system design. This ensures your ROI compounds year over year.

Engineered for global compliance & longevity

In today's regulated environment, compliance isn't a feature-it's the foundation. Our robotic design specification process embeds standards from day one.

US Market Standards

- ANSI/RIA R15.06 (Industrial Robot Safety)

- OSHA 29 CFR 1910 Subpart O (Machinery)

- UL 1740 (Robot & Robotic Equipment)

- Industry-specific (FDA 21 CFR Part 11 for Pharma, etc.)

EU Market Standards

- Machinery Directive 2006/42/EC (CE Marking)

- ISO 10218-1/2 (Robotic Safety)

- ISO/TS 15066 (Collaborative Robots)

- IEC 61508 (Functional Safety - SIL 2 Capable)

- GDPR-compliant Data Architecture

Our performance warranty & IP promise

- 24-Month system performance warranty: We guarantee the system will meet or exceed the KPIs defined in Phase 1. If it doesn't, we fix it at our cost.

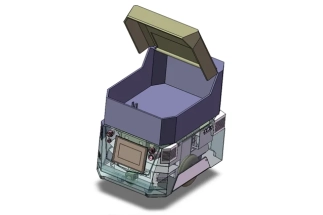

- 100% IP ownership: All custom code, algorithms, and robotics studio design documents are your property. We provide patent-supporting documentation.

- Delivery model flexibility: Choose full source code transfer, a perpetual license for the core engine, or a hybrid model. All include full documentation and training.

Answers to your strategic questions

What specific ROI can I expect from a custom decision-making system?

Our clients typically achieve 25-40% reduction in operational labor costs, 30-50% faster cycle times, and ROI within 12-18 months. For example, a Midwest automotive supplier reduced quality-related downtime by 67% ($2.1M annual savings) using our robotic performance optimization design. We build a detailed financial model during Phase 1 specific to your operation.

How do you handle compliance with both US and EU regulations?

We engineer dual-compliance into every system. For the US: ANSI/RIA R15.06, OSHA guidelines, and industry-specific standards. For the EU: CE Marking under the Machinery Directive 2006/42/EC, ISO 10218-1/2, ISO/TS 15066 for collaborative systems, plus GDPR-compliant data handling. Our robotic design specification process includes a compliance audit trail accepted by TÜV and other notified bodies.

What happens to our intellectual property?

100% Your IP. Zero Vendor Lock-in. This is our core promise. You retain complete ownership of all custom algorithms, robotic system architecture design blueprints, and application code. We transfer everything upon final payment with full documentation. Many clients protect this IP with patents—we provide the necessary technical disclosures.

Can we start with a pilot before full commitment?

Yes. Our Risk-Free Proof of Concept starts at $45,000. In 6-8 weeks, we'll deploy a minimal viable system targeting your highest-value pain point (e.g., sorting defect reduction or dynamic scheduling). You see measurable results before scaling. 85% of pilot projects convert to full implementation with adjusted costs based on pilot learnings.

How do you integrate with our existing legacy equipment and SAP/ERP?

Our systems are built with open APIs and middleware that already interface with Siemens, Rockwell, Fanuc controllers, and SAP/Oracle/MES layers. We've connected to equipment dating back 15+ years. A key part of our robotics development design process is a full integration audit to prevent production disruption.